Geometries and materials have a significant influence on the acoustic and mechanical behaviour and thus on the reproduction qualities of a loudspeaker. No manufacturer can avoid the diffraction, interference, resonance and fractionation phenomenas, and all membranes, whatever their shape and material, are affected by these physical behaviours.

-

Take two identical materials, each geometry has its own radiation characteristic which includes diffraction and interference phenomena, they are responsible for directivity and sudden variations of off-axis pressure in high frequencies.

-

Take two identical shapes, each material has its own linear and non-linear vibratory behaviour, which includes resonance and fractionation phenomena. These cause amplitude and phase accidents, influencing the directivity and harmonic distortion.

Introduction

Regardless of the diameter, geometry or nature of the diaphragm (treated paper, magnesium, ceramic, polypropylene, aluminium or other composites) and regardless of the motor (magnet, voice coil), all loudspeakers have an optimal operating limit for their diaphragm. This limit is characterized by a maximum frequency, the frequency at which the axial displacement of the diaphragm is no longer perfectly uniform.

In electroacoustic jargon, this phenomenon is also called “moving part fragmentation”, which means that the diaphragm becomes deformed, buckles, creates undulations and reproduces perfectly audible resonances, which are reflected in the listening experience by a more or less pronounced colorings of the sound message.

Here is how PM filtering solves this problem…

![CSD2[1]](https://www.recital-audio.com/wp-content/uploads/2020/07/CSD21.jpg)

Most bass and midrange drivers begin to fragment at a frequency that is far too low for a tweeter to take over, as it is simply not designed for it.

Indeed, this frequency, which depends largely on the stiffness of the membrane and therefore on the material of which it is made, is only around 800Hz for a ‘standard’ 17cm loudspeaker equipped with a ‘soft’ membrane made of polypropylene, paper or other variants.

HI-FI tweeters, even the most efficient ones, are unfortunately not designed to go down this low in frequency because of their small emissive surface, and therefore there is no alternative but to allow the bass/midrange driver to reproduce a frequency range in a denatured way. This partly explains the fact that all loudspeakers sound different.

Membrane selection

In order to reproduce music with absolute transparency, it is therefore imperative that no membrane deformation creates disturbances, and this, across the entire audible bandwidth (20Hz-20,000Hz). The Pure-Motion crossover technology responds to this need by ensuring that the loudspeakers behave in a safe mechanical way, without any fractionation of the moving parts.

This is why all our loudspeakers are equipped with very rigid aluminium or aluminium/magnesium alloy drivers. This is why all our loudspeakers are equipped with very rigid aluminum or aluminum/magnesium alloy drivers. Below is a comparison of the typical behaviour of a soft (slider to the right) and rigid (slider to the left) membrane for an 18cm diameter speaker.

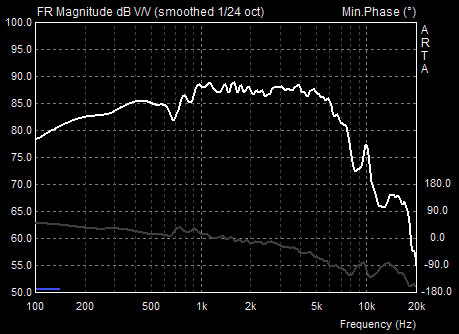

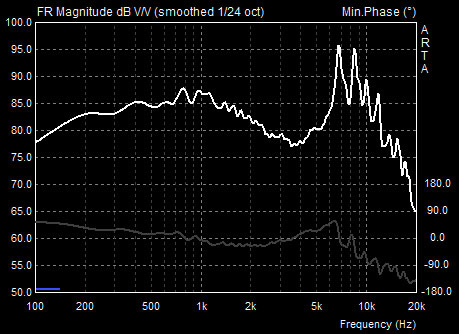

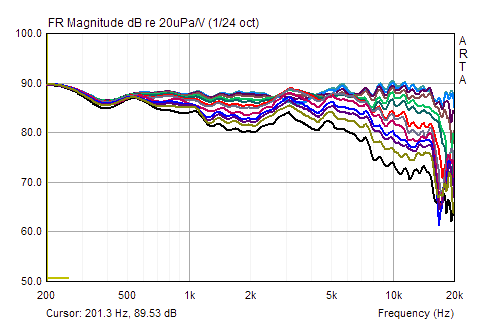

Freq response

Soft diaphragm (left) ; accident on the frequency response at 700Hz, sign of the first fractionations. Rigid diaphragm (right) ; very marked resonances only occur from 5kHz

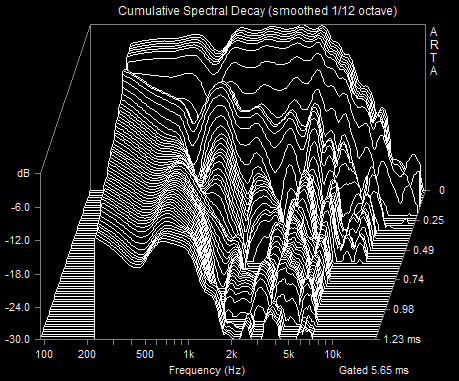

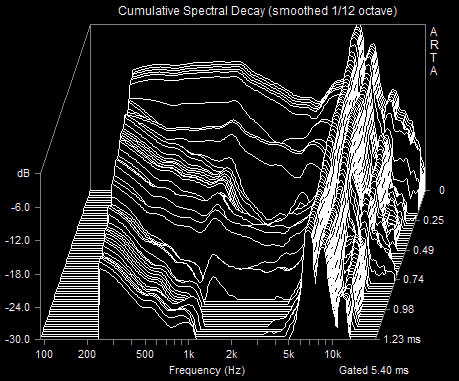

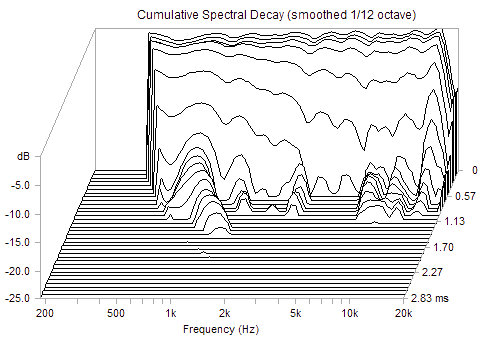

CSD

Soft diaphragm (left) ; numerous resonances occur even at low frequencies, sources of sound signature. Rigid diaphragm (right) ; the resonances are all concentrated in the frequencies above 5kHz.

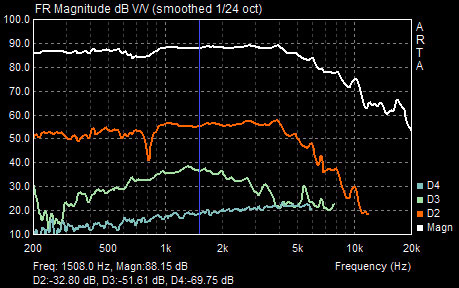

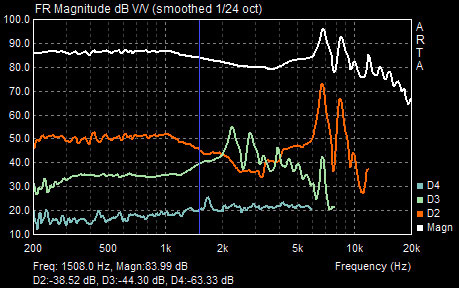

Distorsion

Soft diaphragm (left) ; homogeneous distortion over the whole bandwidth. Rigid diaphragm (right) ; 2nd and 3rd order harmonics are amplified by resonances, which requires specific filtering (PM)

Filtering

To implement this technique, we use transducers with very rigid metal diaphragms whose resonances are all concentrated in the higher frequencies, well outside the effective frequency range that we want each speaker to transmit.

![CSD-L16RNX[1]](https://www.recital-audio.com/wp-content/uploads/2020/07/CSD-L16RNX1.jpg)

Thanks to the filtering, all the loudspeakers work “in piston” throughout their useful operating range, which is what gives Recital-Audio loudspeakers their ability to reproduce music without adding the slightest sound coloration.

![fonction-de-transfert-enceinte-acoustique[1]](https://www.recital-audio.com/wp-content/uploads/2020/07/fonction-de-transfert-enceinte-acoustique1.jpg)

Optimisations

Like a conventional crossover, this passive filtering technique ensures that the music signal is divided and redistributed to each speaker. However, Pure-Motion crossover goes much further by optimising the transfer functions, thus responding precisely to the intrinsic acoustic characteristics of the loudspeakers and the cabinet.

Equipped with high quality passive components, the Pure-Motion crossover incorporates adaptations and compensations that make the loudspeaker perfectly transparent and neutral.

The signal separation is 6-24dB/oct and has a low crossover frequency so that the diaphragm is not prone to mechanical resonance.

Thus, we take care to apply this crossover at a frequency that is at least three times lower than the first resonance frequency of the membrane. This ensures that the loudspeakers have very low distortion levels and a faithful reproduction of the sound message.

The Pure-Motion crossover technology, with its atypical tweeter transition frequency, also ensures extremely low and homogeneous directivity in both the horizontal and vertical axis.

This has the advantage of facilitating the placement of the HIFI loudspeaker while offering a rich and detailed sound throughout the room, but also and most importantly, reproducing a wide stereophonic image.

Internal components

The internal electrical circuits are, in a way, the nerve center of the loudspeaker. At Recital, we pay the most careful attention to the crossover components of the loudspeakers, as well as the internal wiring network.

![Câbles-enceinte-HIFI-2[1]](https://www.recital-audio.com/wp-content/uploads/2020/07/Câbles-enceinte-HIFI-21.jpg)

Invisible to the user and therefore very often neglected in favour of lower manufacturing costs, from the terminals to the loudspeakers, the internal components nevertheless play an important role in the overall design and sound quality of a loudspeaker.

In our opinion, all parts and components must be selected carefully and intelligently in order to provide maximum satisfaction and sound quality. This is why Recital loudspeakers are exclusively equipped with components, connectors and cables that are not only top-of-the-range, but also and above all perfectly suited and dimensioned according to their role and their position in the loudspeaker’s electrical diagram.

Although PM filtering technology requires a relatively large number of passive components for complete efficiency, extensive optimisation of the circuitry means that only the minimum amount of them is used in the audio signal path.

The bass and bass-midrange filter cells have massive inductors of up to 1kg per unit. Made of enamelled copper wire with a large cross-section, these inductors are wound on magnetic supports to reduce resistive losses. The selected cores are SMC (Soft Magnetic Composites) and have excellent magnetic properties: high saturation induction, good permeability and very low hysteresis losses. Your loudspeakers benefit from a lively and dynamic low-midrange register, under perfect control of the amplifier.

![filtre-enceinte-acoustique[1]](https://www.recital-audio.com/wp-content/uploads/2020/07/filtre-enceinte-acoustique1.jpg)

For perfect neutrality in the higher frequencies, other inductors more specific to impedance adaptations are used. These inductors can be of the “air” type or “magnetic core” type and have specially optimised characteristics (inductance/resistance) to obtain surgically precise transfer functions. Moreover, all the capacitors used are metallized polypropylene film type, with great precision, they play their role of pure filtering capacitance without bringing any sonority due to the component itself.